Geotextiles are permeable or porous fabrics, made from synthetic materials that are used in association with soil, have the ability to separate, filter, reinforced, and drain.

As per ASTM, geotextiles are permeable sheets of synthetic fiber like polyester, polypropylene, nylon, viscose, etc. Geotextile fabrics come in three basic forms: woven (resembling mail bag sacking), needle punched(resembling felt), or heat bonded(resembling ironed felt). Geotextiles are available in thickness varying from 10 to 300 miles(1 mil=1/100 inch=0.254mm)and in widths up to 10 m and in rolls length up to 600 m. The permeabilities of geotextiles sheets are comparable in the range from coarse gravel to fine sand.

Geotextile can be made of a wide variety of natural shavings etc. and synthetic materials and can be woven, made up to monofilament, multifilament on tapes, or non woven i.e., mechanically bonded (needle punched), heat bonded or resin bonded. They may also be knitted sometimes.

What is geotextile in civil engineering?

Geotextiles are very useful material in civil engineering works. Geotextiles are used in the construction of roads, highways, railways, airports, bridges, and tunnels.

Types of Geo Textile

Geotextiles are used in both large scale civil engineering projects and small. The geotextile is further prepared in three different categories –

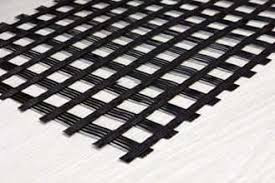

1) Woven Fabrics

2) Non-woven Fabrics

3) Knitted Fabrics

Woven Fabrics –

The most commonly found geotextiles are the woven which are similar to weaving usual clothing textiles. They are high tensile strength and load capacity hence used when you need something very sturdy & durable. Woven fabrics are often created on a loom, and made of many threads woven on a warp and weft.

Non-woven Fabrics –

Non-woven geotextiles are made of 100% staple polyester and polypropylene needle punched filter fabric. The bonding of fibers is done using thermal, chemical, or mechanical techniques or a combination of techniques. They have excellent water flow rates and drainage for the filtration of soil fines but they have a shorter life than woven geotextiles.

|

| NON-WOVEN FABRICS |

Knitted fabrics –

The knitting process consists of interconnecting loops of yarn on powered automated machines. Knitted geotextiles are a subset of woven geotextiles and are mostly as filters on pipes as in two-stage filter applications.

Apart from these three geotextiles, other geosynthetics used are geonets, geogrids, geocells, geomembranes, geocomposites, etc.

Advantages of geotextiles:-

The biodegradable nature of natural fibers have restricted their use to some specific applications whereas synthetic materials have made their way for wide applications. Another advantage of using these fibers for geotextiles are related to their ability to be engineered chemically, physically and mechanically to suit particular geotechnical engineering applications.

Functions of Geotextiles:-

The functions of geotextiles can be broadly divided into two heads –

1) Hydraulic functions

Fluid transmission or drainage

Filtration

2)

Mechanic functions

Separation

Protection

Reinforcement.

USE OF GEOTEXTILES IN EARTHEN DAM CONSTRUCTION

In earthen dams, the upstream and downstream slopes are prone to erosion. Hence geotextiles can be effectively and conveniently used as filter media in erosion control of earthen dam slopes.

In earthen dams, geotextiles can be used in many important positions for filtration, drainage and erosion control functions such as the follows:

Erosion control or slope protection function.

Filtration and drainage material for seepage control system

Filtration and separation function.

Filter wraps around PVC, perforated rigid pipes.

USE OF GEOTEXTILES IN ROAD WORKS

In many places in India, the high water table of the subgrade is a constant concern to read engineers. Geotextiles in the subgrade-subbase interface of a road can effectively deal with this problem.

Provision of geotextiles in road works may serve three functions:

Separator function

Drainage function

Reinforcement function

The function of geotextile as a separator in road work

Geotextile materials provide separation, which preserves the integrity and extends the life of the road surface layer. Roadway pavements are basically structures for taking high contact pressures from the vehicle tries and reducing these pressures through the depth of the pavement to a level that can be supported by the underlying soil/sub-grade.

If geotextile is not provided at the interface between sub-grade and the aggregate base, the vehicle pressure, over time, causes sub-grade soils to migrate into the aggregate base of the pavement section.

Geotextiles also function as filters and separators which –

1) Prevent the interpenetration of the natural soil and aggregates.

2) Fully preserves the properties of road-making materials,

3) Allows vehicles to circulate on the foundation course while working is in progress and protects the foundation course from contamination.

Drainage function of geotextile in road work

Also, using geotextiles to its drainages function, geotextile road edge drains can be laid to provide drainage of roads and hence improving them.

Lastly, when a road embankment is to be constructed on compressible soil, the consolidation of the sub-grade soil, over a period of time will cause cracks and pot in the road surface. To avoid this, usually the procedure is to provide sand drains that accelerate the consolidation process prior to road surfacing. The action can be more effectively achieved by the provision of geotextiles to provide vertical and horizontal drainage systems.

Reinforcement function of geotextile in road embankments

The geotextile layers are placed across the potential rotational failure plane to carry the tensile forces that cannot be carried by an unreinforced soil mass of the embankment.

USE OF GEOTEXTILES IN RAILWAYS WORKS

Geotextiles can be used in railways works to provide the following:

Separation function

Reinforcement function

Water drainage function

0 Comments